Seawater Desalination with Reverse Osmosis Plant

All Reverse Osmosis crops are fundamentally Desalination Crops but desalination is becoming referred to sea drinking water normally.As sea water has quite superior TDS needs quite superior pressure to power sea drinking water by membranes that are distinct then brackish drinking water membranes.

Reverse Osmosis Plant Facts:

A reverse osmosis plant is usually a manufacturing plant, where water is purified and desalinated by forcing water via a membrane, typically referred to as a reverse osmosis method. Water produced by plant RO might be used for a number of functions like desalination, wastewater remedy, along with the reclamation of dissolved minerals.

RO Plant Description

A median drinking water RO plant system necessitates 6 KW hrs of electrical energy to desalinate a single cubic meter of water. Reverse osmosis h2o vegetation needs a number of pre-treatment techniques together with softening, DE chlorination, and anti-scale cure. Adhering to pre-therapy, high amounts of stress send drinking water through a semi-permeable membrane, which retains all contaminants except h2o.

RO Plant Design and style

To enhance the effectiveness and lifetime of the Reverse Osmosis plant, powerful pretreatment from the feed h2o is required. Number of the correct pretreatment will improve effectiveness and membrane everyday living by minimizing:

Fouling

Scaling

Membrane Degradation

RO plant design is consisting of:

Deciding pretreatment requirement of Reverse Osmosis Plant

In case the feed h2o has traces of large metals, it is very recommended to dose some chlorine to change the dissolved significant metals to physical type, the media filter will filter a lot of it inside a ro drinking water purifier plant.

Reverse Osmosis Plant Number of membrane

Membrane elements are a vital Element of RO crops. The proteins (mainly polyamide) that makeup membrane aspects change depending upon the ending clarity and intake water seawater or brackish water etc

Waterman engineers Australia RO plant for seawater desalination

Waterman Engineers in Australia has created a Reverse Osmosis (RO) plant for seawater desalination, which presents quite a few advantages more than other desalination strategies. Here are a few essential advantages of their RO plant:

Strength Effectiveness:

When compared to other desalination procedures like thermal distillation, RO necessitates fewer Electrical power. Waterman Engineers' RO plant makes use of Innovative membrane know-how, letting it to function at reduced pressures and decrease overall Electrical power intake.

Environmental Effect:

RO generates much less brine discharge in comparison to thermal solutions, cutting down the impact on maritime ecosystems. This aligns with Australia's target environmental sustainability and conservation.

Higher H2o Purity:

The RO method effectively eliminates salts, minerals, and impurities, creating superior-good quality freshwater that satisfies stringent consuming h2o specifications. This trustworthiness is vital for furnishing Protected and clean up water to communities.

Modular Style and design:

Waterman Engineers' RO plant employs a modular style, letting for scalability and flexibility. This is particularly beneficial for areas with varying drinking water calls for, as modules can be additional or modified appropriately.

Reduced Footprint:

RO plants normally Have got a smaller physical footprint when compared with thermal desalination crops, which frequently require in depth infrastructure for heating and cooling processes.

Swift Start out-Up and Shutdown:

RO crops can be began and stopped comparatively swiftly, letting for superior responsiveness to switching h2o calls for and emergencies.

Decreased Chemical Use:

Contrary to Several other desalination procedures, RO involves less chemical substances for operation and cleaning, minimizing chemical-related environmental fears.

Regularity in Overall performance:

The RO procedure is considerably less sensitive to feedwater high quality fluctuations than other procedures, guaranteeing a more reliable functionality after some time.

Value-Success:

Although initial Desalination Plant Manufacturer investment expenditures might be substantial, RO crops have a tendency to obtain decrease operational and maintenance expenditures Over time in comparison to thermal procedures.

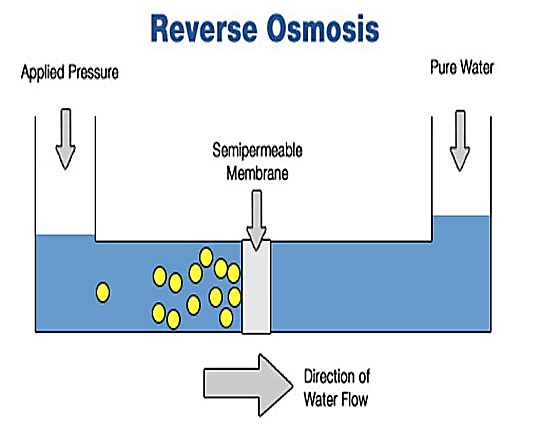

Reverse Osmosis (RO) is actually a h2o purification procedure that works by using a partially permeable membrane to get rid of ions, unwelcome molecules, and larger particles from consuming drinking water. By implementing strain to beat osmotic tension, it permits the passage of h2o molecules while rejecting contaminants, thereby manufacturing clean water on one particular facet of the membrane and concentrated impurities on another.

The Doing work basic principle of the Reverse Osmosis (RO) plant involves applying strain to your saline Alternative to force water molecules through a semi-permeable membrane. This membrane enables only drinking water to move although rejecting salts, contaminants, and impurities, leading to purified drinking water to the permeate aspect and also a concentrated Alternative of contaminants on the brine facet.

Some great benefits of Reverse Osmosis include creating higher-high quality, thoroughly clean water by removing contaminants, being efficient and price-productive eventually, necessitating nominal chemical use, and getting adaptable to various scales of Procedure from modest property techniques to big municipal crops.

RO vegetation have replaced Demineralisation (DM) crops given that they usually provide a extra successful and cost-helpful Option for water purification. RO units Will not need the regeneration substances that resin-based mostly DM crops do and may remove a broader choice of contaminants, which includes dissolved solids and microorganisms.

Waterman Engineers Australia possible employs Reverse Osmosis (RO) crops for seawater desalination by forcing seawater through a semi-permeable membrane to get rid of salt as well as other impurities. This method produces clean, potable h2o in the ocean, addressing drinking water scarcity and providing a sustainable provide for several requirements.